Digital Twin Technology serves as a bridge between the physical and digital worlds by creating a virtual representation of physical assets, systems, or processes. Through real-time data collection and analytics, it allows businesses to monitor performance, predict failures, and optimize efficiency. Essentially, it is akin to a real-time simulation model that dynamically updates as its physical counterpart changes.

In an increasingly data-driven industrial landscape, Digital Twin Technology plays a pivotal role. It finds applications across various sectors—manufacturing, healthcare, agriculture, and energy, to name a few. For instance, in manufacturing, it can help in identifying inefficiencies in production lines, whereas, in healthcare, it can aid in patient flow management. The technology contributes significantly to achieving operational excellence, reducing costs, and enhancing the decision-making process.

This article aims to delve into the key facets of Digital Twin Technology, exploring its applications, benefits, and challenges. While focusing on its role in modern industries, the article also aims to shed light on the current market trends and future potential. The objective is to offer a comprehensive insight into the rising significance of this technology in shaping the future of various industries.

Geographic Distribution of Digital Twin Technology Adoption

The geographic distribution of Digital Twin Technology adoption paints a global picture of varying engagement. North America currently leads, accounting for a substantial portion of overall adoption. Europe and Asia-Pacific are also substantial players, recognizing the operational efficiencies and decision-making advantages offered by Digital Twins. Meanwhile, emerging markets in Latin America and the Middle East & Africa are slowly getting into the game.

What is Digital Twin Technology?

Digital Twin Technology is a computational framework that creates a virtual replica of physical objects, systems, or processes. This digital model serves as a parallel to its physical counterpart, allowing for real-time monitoring, analysis, and control. The technology encompasses not just a 3D representation but integrates algorithms, data analytics, and machine learning to provide a dynamic model that evolves over time.

Relationship with Physical Assets

The essence of Digital Twin Technology lies in its direct correlation with physical assets. The digital twin acts as a mirror, reflecting the state, characteristics, and performance of its physical counterpart. This enables organizations to remotely track the health and status of assets, detect anomalies, and predict failures before they occur. Thus, digital twins can significantly enhance asset management and lifecycle analysis.

Importance of Real-Time Data

The effectiveness of a digital twin is closely tied to the quality and immediacy of data it receives. Real-time data feeds from sensors and other data points keep the digital model continuously updated. This enables immediate responses to changes, thereby allowing for highly dynamic control and decision-making. In scenarios such as predictive maintenance or emergency response, the value of real-time data becomes immeasurable, potentially saving both resources and lives.

By seamlessly integrating real-time data, digital twins offer a powerful tool for improving operational efficiency, reducing risks, and gaining insights that would otherwise be difficult to obtain.

The Role of IoT in Digital Twin Technology

IoT and Cyber-Physical Systems

The Internet of Things (IoT) serves as the backbone for the functionality of Digital Twin Technology, particularly in the creation of cyber-physical systems. These systems consist of a collaboration between computational and physical processes, where IoT devices collect data from the physical world and transfer it to the digital twin.

Role of Sensors and Actuators

Sensors and actuators are integral components in the IoT ecosystem that power digital twins. Sensors collect real-time data about various attributes—such as temperature, pressure, and moisture—from the physical asset and feed it to the digital model. Actuators, on the other hand, enable the digital twin to interact with its physical counterpart by sending commands for control operations. For example, in a digital twin of a manufacturing system, sensors can provide data on machine temperature or assembly line speed, while actuators can adjust these parameters as needed.

Networking Protocols in Data Collection

The efficiency of a digital twin heavily depends on the seamless and reliable transfer of data, for which networking protocols play a crucial role. Protocols like MQTT, CoAP, and HTTP are commonly used to facilitate this data exchange. These protocols ensure that data is collected and transmitted securely and efficiently, minimizing latency and maximizing reliability.

By combining IoT technologies, sensors, actuators, and networking protocols, Digital Twin Technology opens up new avenues for system optimization, predictive maintenance, and real-time decision-making across various industries.

Technologies and Tools Supporting Digital Twin

Data Model Architecture

The foundation of any effective Digital Twin Technology is its data model architecture. This architecture defines how data is collected, processed, and used for simulation and analysis. Typically, the data model consists of a combination of static metadata, like design specifications, and dynamic data, such as real-time sensor feeds. According to a Gartner report, 75% of enterprises that employ digital twins use at least three different types of data models, signifying the complexity involved in effective digital twin setups.

Cloud Computing vs. Edge Computing

Digital twins can be deployed either in cloud environments or at the edge, closer to where the data is generated. Cloud computing offers the advantages of scalability and powerful computational resources. In contrast, edge computing provides lower latency, which is crucial for real-time data processing and decision-making. A study by Forrester found that 60% of businesses implementing digital twin technology are using a hybrid model that incorporates both cloud and edge computing to harness the benefits of both paradigms.

APIs and Integration

Application Programming Interfaces (APIs) are crucial for the successful deployment and scalability of digital twins. They facilitate the seamless exchange of data between the digital twin and other systems like Enterprise Resource Planning (ERP) or Product Lifecycle Management (PLM) tools. Moreover, APIs enable the integration of machine learning algorithms and advanced analytics capabilities into the digital twin, making them more intelligent and adaptable to changes.

By comprehending the roles and intricacies of data model architectures, cloud and edge computing, and APIs, one can better appreciate the multidimensional nature of Digital Twin Technology and its expansive utility across sectors.

Different Types of Data in Digital Twin

Structured and Unstructured Data

Digital Twin Technology utilizes both structured and unstructured data to create a comprehensive digital replica. Structured data, such as sensor readings and machine logs, are easily categorized and analyzed. Unstructured data, like images or natural language inputs, require more complex algorithms for interpretation. According to IDC, approximately 90% of the data generated in a digital twin setup comprises unstructured data, highlighting the need for advanced analytics tools for data interpretation.

Time-Series Data

Time-series data is a crucial component in digital twins, allowing for the monitoring of changes over a specific period. This data type is vital for trend analysis, anomaly detection, and predictive maintenance. For example, in a digital twin of a wind turbine, time-series data can capture variables like wind speed, blade rotation, and energy output over time to predict when the turbine might fail or require maintenance.

Geospatial and Multidimensional Data

Digital twins often employ geospatial and multidimensional data to represent objects in their real-world context. This can be particularly useful in sectors like urban planning and logistics. According to a Markets and Markets report, the geospatial analytics market is expected to grow to $21.0 billion by 2025, much of which can be attributed to its integration in digital twin technology.

Understanding the types of data that populate a digital twin—structured and unstructured, time-series, and geospatial—can provide insights into the complexity and capabilities of these digital replicas. Accurate and diverse data inputs enable digital twins to serve as highly effective tools for analysis, prediction, and control across a variety of applications.

Applications of Digital Twin Technology Across Industries

Manufacturing and Production

Digital Twin Technology has revolutionized the manufacturing and production industries. It allows for real-time monitoring of equipment, making it easier to anticipate problems before they occur, thereby extending machine life and reducing maintenance costs. The technology is primarily used for predictive maintenance, process optimization, and quality control. These applications have shown significant improvements in operational efficiency within organizations.

Healthcare Systems

In healthcare, digital twins are not just limited to machinery or buildings; they extend to creating digital replicas of biological systems for personalized treatment. Digital twin technology has contributed to substantial advancements in diagnostics, patient care, and equipment maintenance. It has the potential to deliver highly personalized treatment plans based on real-time patient data, and is poised to become a cornerstone for the next wave of medical innovations.

Smart Cities and Infrastructure

The role of digital twins in smart cities is multifaceted. From urban planning and disaster response to resource management, these digital replicas provide a high-resolution model of urban life. They help in monitoring environmental conditions, traffic patterns, and public utilities, aiding municipal authorities in making data-driven decisions. The technology contributes to more efficient and sustainable cities.

Supply Chain and Retail

Supply chain management has become incredibly complex, given today’s global reach. Digital twins provide real-time data and analytics, which are critical for tracking the movement of goods, predicting logistical bottlenecks, and automating warehouse operations. Retailers can also use digital twins for optimizing inventory levels, improving customer service, and personalizing shopping experiences.

Aerospace and Automotive Sectors

Digital twins have seen considerable adoption in aerospace and automotive industries. They are mainly used in the design and manufacturing processes, reducing time-to-market and ensuring product reliability. These digital replicas simulate real-world conditions to assess product performance, thus offering a cost-effective and risk-free way to test new designs and operational strategies.

Retail

In the retail sector, digital twins are used for enhancing the customer experience through personalized recommendations and real-time inventory management. Retailers employ this technology to gain insights into consumer behavior, optimize stock levels, and predict future sales trends.

Operational Aspects of Digital Twin Technology

Data Collection and Analysis

Data collection and analysis form the backbone of any digital twin system. Real-world data, harvested through an array of sensors and IoT devices, are continuously fed into the digital twin model. This data forms the basis for real-time monitoring, performance analysis, and long-term predictions. High-quality, timely data is crucial for the system’s efficacy. According to a study by McKinsey, data-driven organizations are 23 times more likely to acquire customers and 6 times as likely to retain them compared to non-data-driven organizations.

Data Visualization Techniques

Data visualization is pivotal in making the complex data streams of a digital twin comprehensible for decision-makers. Visualization techniques such as dashboards, heat maps, and 3D models allow engineers and analysts to interact with the digital twin in an intuitive manner. These tools help in understanding trends, identifying anomalies, and making timely decisions. According to Gartner, by 2025, data visualization will be integrated into 90% of enterprise applications to improve decision-making.

Predictive Analytics and Machine Learning

The real value of a digital twin comes into play with predictive analytics and machine learning. These advanced technologies allow the system to learn from past data, recognize patterns, and make forecasts about future conditions or failures. Predictive analytics can potentially save organizations millions in maintenance and operation costs. Forrester reports that insight-driven firms are growing at an average of 30% annually and are on track to earn $1.8 trillion by 2021.

Automation and Optimization

Digital twins facilitate the automation of various processes by providing a data-rich, real-time digital replica of physical systems. Through this digital representation, operators can test different scenarios for system optimization without affecting the real-world counterpart. Automation enabled by digital twins has been found to reduce machine downtime by up to 20%, according to a report from Accenture.

By understanding these operational aspects, it becomes evident how Digital Twin Technology serves as a powerful tool for companies aiming to leverage data for insightful decision-making and operational excellence.

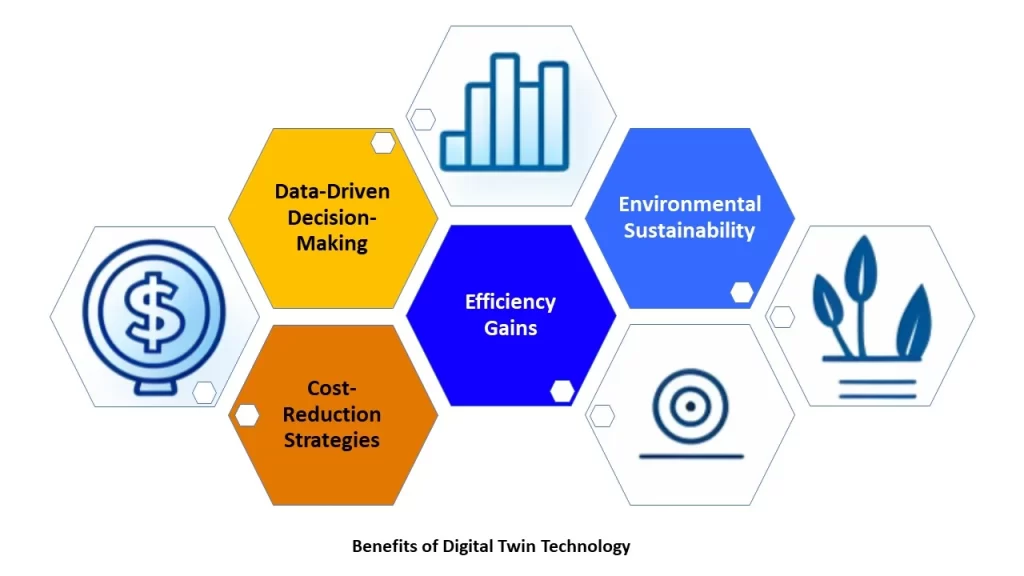

Benefits of Implementing Digital Twin Technology

Efficiency Gains

Implementing digital twin technology offers substantial efficiency improvements. Companies using digital twins report up to a 25% improvement in operating efficiency according to a study by Deloitte. Digital twins streamline the monitoring and troubleshooting process, thereby reducing the time spent on manual data collection and interpretation. They allow for real-time adjustments that can significantly enhance productivity.

Cost-Reduction Strategies

Cost savings are another major benefit of this technology. Deloitte reports that digital twin implementation can reduce asset downtime by up to 20%, translating into significant savings. Moreover, predictive maintenance can save industries like manufacturing billions annually by proactively identifying mechanical issues before they cause failures.

Data-Driven Decision-Making

Digital twins make data-driven decision-making not just possible, but efficient. As per a report by McKinsey, organizations that leverage data analytics have a 23 times higher likelihood of outperforming their competitors in terms of customer acquisition. This fosters a more agile business environment that can adapt to market changes more rapidly than traditional models.

Environmental Sustainability

There’s also a significant environmental aspect. Digital twins allow companies to optimize resource allocation better, which in turn can substantially reduce waste and emissions. According to a PwC report, smart manufacturing techniques, including digital twins, could reduce greenhouse gas emissions by up to 4.3 gigatons per year by 2030.

By understanding these benefits, companies can better assess the strategic value that digital twin technology offers, in terms of operational improvements and sustainability metrics.

Security and Privacy Concerns

Data Encryption Techniques

The deployment of digital twin technology comes with its set of security challenges, the foremost being the necessity of robust data encryption techniques. According to a report by Symantec, 71% of enterprises list data encryption as a top priority in their security strategy. In the context of digital twins, secure encryption algorithms are vital in safeguarding sensitive data during transmission and storage.

Compliance with Regulatory Bodies (GDPR, HIPAA)

Another critical aspect is compliance with regulatory bodies such as GDPR in Europe and HIPAA in the United States. These regulations mandate stringent data protection measures and failure to comply can result in severe penalties. The Global State of Information Security Survey reveals that 88% of surveyed companies have made compliance readiness a business priority. For digital twin technology to be universally adopted, it needs to be in full compliance with these data protection laws.

Data Integrity and Cybersecurity Measures

Maintaining data integrity and robust cybersecurity measures are also of paramount importance. According to Cybersecurity Ventures, damages from cybercrime are expected to reach $6 trillion annually by 2021. Digital twins, with their extensive data storage and complex interfaces, are potentially vulnerable to cyber-attacks. Therefore, investing in advanced cybersecurity measures such as multi-factor authentication and real-time monitoring is crucial for safeguarding the integrity of the digital twin ecosystem.

Challenges and Risks

Scalability Issues

While digital twin technology offers several advantages, scalability remains a significant challenge. As businesses grow, so does the complexity and volume of data that digital twins must handle. According to a Gartner report, 21% of companies cite scalability as a major barrier to digital transformation. Failing to scale digital twin solutions effectively can lead to bottlenecks that undermine operational efficiency.

Integration Complexity

Another hurdle is the complexity involved in integrating digital twins with existing systems. An IBM study found that 85% of all data integration projects fail to meet objectives due to the complexity involved. Digital twin technology often necessitates the use of multiple software solutions, including IoT devices, APIs, and data analytics tools, making integration a daunting task.

Data Accuracy Concerns

Data accuracy is also a pressing issue. Digital twins rely on precise, real-time data to be effective. A report by Forrester highlights that 33% of companies struggle with inaccurate data, which can severely hamper decision-making processes. In the context of digital twins, inaccurate data can lead to incorrect analyses, thereby compromising the system’s reliability and efficacy.

Financial Costs

Lastly, the financial aspect cannot be ignored. Initial setup and maintenance costs for implementing digital twin technology can be substantial. According to an Accenture study, enterprises spend an average of 5.2% of their annual revenue on digital transformation projects, including technologies like digital twins. These costs may deter smaller businesses from adopting the technology, despite its long-term benefits.

Understanding these challenges and risks allows companies and stakeholders to make more informed decisions when considering the implementation of digital twin technology.

Digital Twin Technology Case Studies

ICONS IMAGE

Siemens Gas Turbine Maintenance

Siemens employed digital twin technology to optimize the maintenance of their gas turbines. The digital twin models helped the engineers to simulate various stress factors and wear-and-tear scenarios, leading to more targeted maintenance. This approach resulted in a 30% reduction in unplanned downtime and increased operational efficiency. It serves as an exemplary use case for predictive maintenance in heavy industries.

General Electric and Healthcare Imaging

General Electric (GE) applied digital twins to healthcare imaging devices like MRI and CT scanners. The digital twins provided real-time analytics on device performance and usage, leading to a 25% reduction in system outages and improved patient throughput. GE’s initiative showcases the applicability of digital twins in the healthcare sector for device optimization.

Port of Rotterdam and Water Management

The Port of Rotterdam used digital twins for efficient water management. By integrating IoT sensors and real-time analytics, they could predict tide levels and optimize ship traffic. The result was a 20% improvement in port capacity and significant cost savings in logistics. This case study exemplifies the utility of digital twins in smart city applications.

Tesla and Automotive Design

Tesla utilized digital twin technology for the design and testing of new vehicle models. By simulating different road conditions and vehicle stresses, Tesla could rapidly iterate designs and get to market faster. The company credits digital twins with a 15% reduction in design-to-market time.

Walmart and Supply Chain Optimization

Walmart implemented digital twins to streamline its supply chain operations. The digital models helped in tracking product inventory, predicting demand, and automating restocking procedures. As a result, Walmart achieved a 10% increase in supply chain efficiency, demonstrating the potential of digital twins in retail logistics.

Top Companies in Digital Twin Technology

Siemens

Siemens is one of the pioneers in the field of digital twin technology. The Germany-based multinational has integrated digital twins into a wide range of sectors, including manufacturing, energy, and healthcare. Recently, the company announced the expansion of its digital twin platform to include a more extensive set of IoT tools. In terms of competitive analysis, Siemens remains a significant player due to its comprehensive offerings and strong market presence.

General Electric (GE)

GE is another industry leader, particularly focusing on healthcare, aviation, and energy sectors. They have been in the news for their partnership with Microsoft to bring their digital twin technology to the Azure cloud platform. Competitive analysis shows that GE has been aggressively pushing for adoption, backed by their long-standing experience in industrial solutions.

IBM

IBM, a tech giant, has leveraged its Watson IoT platform to develop sophisticated digital twin solutions. IBM’s focus has been on smart cities and infrastructure, recently securing a deal with the City of Seoul for urban planning. In terms of competitive analysis, IBM is highly innovative but faces competition from companies that have specialized only in digital twins.

Dassault Systèmes

France-based Dassault Systèmes has made a significant mark in digital twin technology, particularly in aerospace and defense. They recently announced a collaboration with Boeing to develop digital twins for airplane manufacturing. The competitive landscape indicates that Dassault’s expertise in 3D design gives them a unique edge. Dassault Systèmes’ collaboration with Airbus serves as a noteworthy business case study in aerospace.

AVEVA

UK-based AVEVA specializes in digital twin technology for industrial organizations. Recent news highlights their acquisition of OSIsoft to enhance their data analytics capabilities. Competitively, AVEVA’s strength lies in their focus on niche industrial sectors like oil and gas. AVEVA has a compelling case study in optimizing water treatment plants through digital twin technology.

Future Outlook

Evolving Technologies and Tools

The landscape of digital twin technology is continuously evolving, driven by advancements in related fields like artificial intelligence, IoT, and machine learning. The expansion suggests that emerging technologies will significantly influence the capabilities and applications of digital twins.

Anticipated Industry Trends

Several industry trends are likely to shape the future of digital twin technology. One such trend is the increasing integration of digital twins with 5G networks for real-time data analysis. A survey by McKinsey reveals that 63% of companies are actively investing in 5G technology to bolster their digital transformation efforts, including digital twin implementations. Additionally, more industries like healthcare, aerospace, and smart cities are expected to adopt this technology for a range of applications from patient monitoring to urban planning.

Role of Stakeholders in Future Developments

The stakeholder community around digital twins, including policymakers, vendors, and end-users, will play a crucial role in the technology’s evolution. According to a Deloitte study, public-private partnerships are anticipated to grow by 24% in the next five years, focusing on the development and governance of emerging technologies like digital twins. These collaborations are expected to foster innovation, set industry standards, and ensure more widespread and ethical use of the technology.

Through understanding these future perspectives, companies can better prepare for the evolving landscape of digital twin technology, thereby maximizing their potential benefits and minimizing risks.